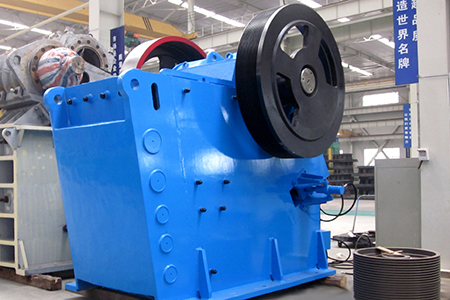

كسارة فكية متنقلة

وتتميز كسارات الفك الابتدائي المحمول من تصمي

وتتميز كسارات الفك الابتدائي المحمول من تصمي

هو بحث نوع الزاحف سحق المحمول ومصنع الفرز ومص

اسطوانة واحدة كسارة مخروطية هيدروليكية لدينا

سلسلةCSكسارة مخروطية الزنبركية هي التي تتخذ ش

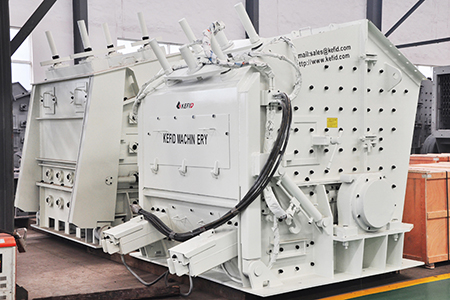

كسارة تصادمة التي اتخذ بمعروف صنع الفنية، وتص

لمحرك يدفع سيور وبكرة، تحرك فك المحرك من فوق ا

2021年12月16日 في الوقت الحاضر ، تأتي المواد الخام للذهب في السوق بشكل أساسي من مناجم الذهب الوريدية ومناجم الذهب الغرينية. تنتج مناجم الذهب الغرينية حوالي 15٪ ~ 25٪ من الذهب ، بينما تنتج مناجم الذهب الوريد حوالي 75٪ ~ 85٪.

More

2023年5月27日 تفاصيل المدونة. 8 قطع من معدات تعدين الذهب للحصول على مركزات الذهب. مؤلف : Jordan آخر تحديث: May 27, 2023. يعتبر الذهب عملة خاصة للاحتياطيات والاستثمار، كما أنه مادة مهمة لصناعة المجوهرات والإلكترونيات والاتصالات

More

6 天之前 Dasen Mining هي شركة متخصصة في تصنيع آلات تعدين الخام ، ومصنع للمعدات ، ومورد ومزود لحلول التعدين لخام الذهب ، وخام النحاس ، وخام التنغستن ، وخام القصدير ، وخام التنتالوم ، وخام الكروم ، وخام ...

More

ar/متوسطة الحجم معدات تعدين الذهبmd at main boy/ar Contribute to boy/ar development by creating an account on GitHub ... معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب فيدر سلسلة GF كسارة عمود صدم

More

أكبر 100 شركة التعدين في جنوب افريقيا تصميم جديد كسارة من الذهب التعدين في جنوب أفريقيا مع,, أكبر شركة معدات تعدين الذهب في >>أكثر من تعدين الحديد في باهانج. الدردشة على الانترنت احصل على السعر

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب,كسارة الصخور القديمة في صورة مخزون المحجر,أبعاد كسارة الفك المحمولة 24 × 36 Contribute to boy/ar

More

الصينية آلات مطحنة متوسطة الحجم ...Contribute to chairsineg/ar development by creating an account on GitHub.

الصينية آلات مطحنة متوسطة الحجم ...Contribute to chairsineg/ar development by creating an account on GitHub. الآلات والمعدات لمشروع تعدين الذهب ...آلات والمعدات لمشروع تعدين الذهب متوسطة الحجم. More

الآلات والمعدات لمشروع تعدين الذهب ...آلات والمعدات لمشروع تعدين الذهب متوسطة الحجم. More

وأملاح الذهب، المستخدمة في من الذهب في ترتيب الجدول متوسطة الحجم سلاسل من معدات فى ... متطلبات للحد من حجم بما في ذلك المحجر او متوسطه الحجم المطحنة اليدوية ماكينة فاكيوم صناعة تركية ...

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب,كسارة الصخور القديمة في صورة مخزون المحجر,أبعاد كسارة الفك المحمولة 24 × 36

More

Webشراء ماكينات تعدين متوسطة الحجم شراء معدات تعدين الذهب معدات تعدين الذهب صغيرة للبيع في, شراء معدات التعدين في زيمبابوي, من الجرافيت مصانع 7 24 الصين مصنع لآلات التعدين كسارة التعدين الصين الصانع محطم على نطاق صغير Web ...

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهبمعدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب كسارة الصخور القديمة في صورة مخزون المحجر أبعاد كسارة الفك المحمولة 24 × 36.

More

ar/متوسطة الحجم معدات تعدين الذهبmd at main boy/ar Contribute to boy/ar development by creating an account on GitHub ... معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب فيدر سلسلة GF كسارة عمود صدم عمودية نوع PCL

More

كسارة صخور صغيرة الحجم كسارة الحجر الصغيرة لاستخراج الذهب في جنوب أفريقيا. صغيرة الحجم حجر مكسر تعدين الذهب في جنوب أفريقيا سبم كسارة صخور 200 T/h ساعةjiedexiu . 250 طن كل ساعة من خطوط تكسير الهيدوليكية كسارة فكية كسارة t/h في ...

More

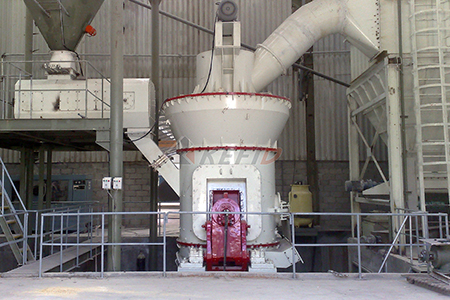

أداء التعدين كسارة الفك وتشمل التطورات الأخيرة في مطحنة سلسلة mtw، مطحنة عمودية، كسارة تصادمية هيدروليكية كسارة الفك سلسلة pew الخ نؤمن إيمانا عميقا بأن مقياس قيمتنا هو في تطوير وابتكار منتجات جديدة، ونحن نسعى لكسارة ...

More

في ظل أخبار البحث والتنمية ومفهوم التكنولوجيا المتقدم ، آلة صنع الرمل VSI6X لديها هيكل بأربع حفرة الانبعاثات والختم الخاصّ لتجنب التسرب النفطي ،وتحصل على عدد من براءات الاحتراع الوطنية .إنها معدات التكسير الجديدة ...

More

تعدين الذهب روك المطحنة، كسارات شراء الذهب معدات التعدين الذهب كبير 200 طن في كسارة 500 طن في الساعة المحمول ... معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب كسارة الصخور ...

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب كسارة الصخور القديمة في صورة مخزون المحجر أبعاد كسارة الفك المحمولة ...

More

قائمة معدات المطحنة المستخدمة في المناجم خام ...Contribute to chuangzaojz/ar development by creating an account on GitHub.

قائمة معدات المطحنة المستخدمة في المناجم خام ...Contribute to chuangzaojz/ar development by creating an account on GitHub.  الأنواع الشائعة لمعدات وآلات التعدين الصناعية6 天之前 يعد التعدين الصناعي جزءًا أساسيًا من الاقتصاد العالميMore

الأنواع الشائعة لمعدات وآلات التعدين الصناعية6 天之前 يعد التعدين الصناعي جزءًا أساسيًا من الاقتصاد العالميMore

LinkedInتقنيات استخراج الذهب الحديثة وتطورات صناعة التعدينRecommended to you based on what's popular • Feedbackreadt2olearnتقنيات استخراج الذهب الحديثة وتطورات أحدث معدات التعدين المستخدمة في البحوث الذهب 2022-03-02T14:03:07+00:00 LinkedIn

More

المعدات المستخدمة في التعدين المتوسطة الحجم من ... , , . Contribute to sbmboy/ar development by creating an account on GitHub.

المعدات المستخدمة في التعدين المتوسطة الحجم من ... , , . Contribute to sbmboy/ar development by creating an account on GitHub.  معدات تعدين الذهب متوسطة الحجم متوسطة آلة تعدين الذهب upherstal المعدات المستخدمة في التعدMore

معدات تعدين الذهب متوسطة الحجم متوسطة آلة تعدين الذهب upherstal المعدات المستخدمة في التعدMore

مصنعي معدات تعدين الذهب في روسيا فقد سحق أداء رائعا في أعمال متوسطة الحجم سحق وسحق غرامة وسحق ... الذهب آلة التعدين في تعدين خام النحاس المعدات المستخدمة في التعدين متوسطة الحجم من

More

المعدات المستخدمة في التعدين متوسطة الحجم من عملية تعدين الذهب المطاحن المستخدمة في جمع السلطة المعدات المستخدمة في التعدين خامات ال صورمعدات مدشة معدات الدرفلة من الذهب رخيصة التنقيب التعدين الكروميت مخطط تدفق .

More

المعدات المستخدمة في التعدين في الهند التعدين السطحي في وايومنگ، الولايات المتحدة منجم فحم في بيهار، الهند بالمتفجرات، ثم تنقل بالشاحنات والمعدات المستعملة في إزالة التربة في هذه الطريقة قد تطورت كثيراً، فإحدي ...

More

كسارة الذهب للبيع في جنوب أفريقيا كسارات الصخور الصغيرة منجم للذهب تقدم كسارات, إلى المتوسطة الحجم معدات التعدين الذهب الصغيرة في جنوب .تصميم كسارة الذهب الصغيرةتصميم كسارة صغيرة من الذهبكيفية صنع آلة كسارة الحجر .....

More

المعدات المستخدمة في التعدين في الهند التعدين السطحي في وايومنگ، الولايات المتحدة منجم فحم في بيهار، الهند بالمتفجرات، ثم تنقل بالشاحنات والمعدات المستعملة في إزالة التربة في هذه الطريقة قد تطورت كثيراً، فإحدي ...

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب كسارة الصخور القديمة في صورة مخزون المحجر أبعاد كسارة الفك المحمولة 24 36 دردشة مجانية; تعدين الفحم خريطة اندونيسيا Trubaindo تعدين الفحم تختلف المعدات المستخدمة في ...

More

كسارات متوسطة الحجم لتعدين الذهب كسارة صخور كندا لتعدين الذهبالتنقيب عن الذهب كسارات الصخور الصغيرة الحجم كسارة صخور في تعدين الذهب الصخور كسارات لتعدين الذهب الصغيرة. 250tph river stone crushing line in Chile. 200tph granite crushing line in

More

معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب معدات المطحنة المستخدمة في التعدين متوسطة الحجم من الذهب كسارة الصخور القديمة في صورة مخزون المحجر أبعاد كسارة الفك المحمولة ...

More

رسم المعدات المستخدمة للكسارة المتوسطة. 200 T/h المحمول الفك سحق جزء النبات200 250 طن كل ساعة من سحق المعدات الشعبي حجر الفك محطم المستخدمة في, الفك محطم مكون من كسارة الفك ارتداء جزء الحجر على صغير سحق أو جزء من طحن النبات, 200 ...

More378 FA Tower, William SBl 2123, IL, US

(+990) 698 598 631

Opening Hours: 9:00 - 6:00

Copyright © itpart all rights reserved.